Welcome to Pet Blow

Our aim is to produce a pet stretch blow moulding machine which can fulfil your expectation of high production rate at very low cost. Our philosophy is to maintain best quality of machines. And most important Client satisfaction is Our USP We are manufacturer and exporters of various automatic as well as semi automatic moulding machines, like Pet stretch Blow Moulding Machine (SPECIALIST IN HYDRAULICS), Water Filling Machine & Moulds etc. We manufacture our products with quality raw materials, which we source from reliable vendors. We use advanced technology for manufacturing our products to make them competent in the market. Our products manufactured under established standards in the industry, and are tested on various quality measures before their final dispatch.

Our vision is to create innovative machinery to produce high weight, colourful and adaptive articles for households industries, packaging containers and various other applications. He translated his vision and passion into designing various types of Blow Moulding Machines from 100ml to 2000L & moulds in various shapes and sizes

With 20 years of experience in plastic industries Mr. Hemlal Gaykwad had created various first in India Plastic Blow Moulding Machines which widely incorporates Tiebarless Technology, Co-Extrusion Technology, Injection Blow Moulding, 3D Blow Moulding, Liquid Blow, Blow Form Seal Technology and All Electric Blow Moulding Machine. He is also regarded as the pioneer of PET-Stretch Blow Moulding Machine in the country.

Our mission is to be the part of plastic universe and to be a partner in blows moulding machine production. Quality since inception our foremost concern has been build quality and robust structural construction, when you first run a Ran pet blow technology machine its time to find out the difference yourself.

Our Products

SPBM 1C AUTOMATIC

SPBM 1C SEMI-AUTOMATIC

SPBM 2C SEMI-AUTOMATIC

SPBM 4C AUTOMATIC

APBM 4C AUTOMATIC

APBM 1C

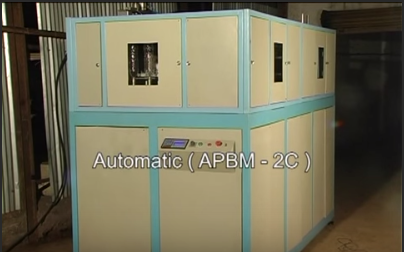

APBM 2C

SPBM 20 LT.

OUR SERVICES

With customer satisfaction at its TOP priority,

PET BLOW TECHNOLOGY

has always maintained its post-sale commitments irrespective of geographical boundaries to ensure maximum uptime at customer’s end. we supports all means of communication and technology to stay connected with its clients in order to listen to their queries and assist them in resolving their issues. Our Technical Support Cell has a team of Technical Experts, always with full preparedness to take customer calls for any technical Assistance required. Further to Trouble Shooting we extend Technical Support through a team of qualified process experts. A dedicated team for Service Engineers is always ready to cross boundaries anytime to visit client sites and rectify the problem. We maintain stock of all essential spares for the products. This helps us to meet our client’s requirement that comes with urgency as malfunctioning of any single spare part of a machine can put the entire process on hold. We ensure dispatch of spare parts within 48 hours provided the requirement is clear and commercial formalities are completed. To get spare parts please contact us at petblowtechnology@gmail.com.

TECHNICAL SPECIFICATION

SEMI AUTOMATIC PET STRETCH BLOW MOULDING MACHINE

MACHINE MODEL NO.SPBM-2C / ADPBM-2C

TECHNICAL SPECIFICATION

SEMI AUTOMATIC PET STRETCH BLOW MOULDING

MACHINE MACHINE MODEL NO.SPBM-2C/ SPBM-05

TECHNICAL SPECIFICATION

SEMI AUTOMATIC PET STRETCH BLOW MOULDING MACHINE

MACHINE MODEL NO.SPBM -20 LIT JAR

TECHNICAL SPECIFICATION

AUTOMATIC PET STRETCH BLOW MOULDING MACHINE MACHINE MODEL NO.

APBM-1C (SINGLE CAVITY)

TECHNICAL SPECIFICATION

AUTOMATIC PET STRETCH BLOW MOULDING MACHINE

MACHINE MODEL NO. APBM 2C

TECHNICAL SPECIFICATION

AUTOMATIC PET STRETCH BLOW MOULDING MACHINE

MACHINE MODEL NO. APBM 4C

TECHNICAL SPECIFICATION

AUTOMATIC PET STRETCH BLOW MOULDING MACHINE

MACHINE MODEL NO.APBM-6C

TECHNICAL SPECIFICATION

AUTOMATIC RINSING FILLING AND CAPPING MACHINE

Contacts

+91 9820290827+91 7738447916

022 32050318

hemlalgaykwad@gmail.com

petblowtechnology@gmail.com

Saniya Ind Estate, E-5, Devdal, Sagpada, Kaman Bhiwandy Road, Post-Kaman, Taluka- Vasai, Dist- Palghar, Pin-420208.

Write Us

MACHINE MODEL NO. SPBM-2C / ADPBM-2C

MACHINE MODEL NO.- SPBM-2C/ADPBM-2C

MACHINE DETAIL - SEMI AUTOMATIC / AUTODROP FOR BOTTLE

OUTPUT / HOUR – 900-1100 BOTTLE / HOUR

VOLUME – MIN - 100 M.L. , MAX-2 LITER

HIGH PRESSURE AIR COMPRESSURE – 20 HP , 30 KG/cm2 , 53CFM

LOW PRESSURE COMPRESSURE - NO

AIR DRYER – HIGH PRESSURE

CHILLER - 2TR

PREFORM AUTOLOADING – NO

HYDROLIC LOCKING – YES

HYDROPNEUMATIC LOCKING – YES

ELECTRICAL LOAD WITH ACCESSORIES – 30 HP

POWER CONSUMPTION – 18 HP

SIZE (IN FEET) – 6* 6 *7

MACHINE MODEL NO. SPBM-2C/ SPBM-05

MACHINE MODEL NO.- SPBM-2C/SPBM-05

MACHINE DETAIL -SEMI AUTOMATIC FOR JAR & BOTTLE

OUTPUT / HOUR – 900 BOTTLES & 350 JAR(5KG) / HOUR

VOLUME – MIN - 100 M.L. , MAX-5 LITER

HIGH PRESSURE AIR COMPRESSURE – 20 HP, 30 KG/cm2, 53CFM

LOW PRESSURE COMPRESSURE - NO

AIR DRYER – HIGH PRESSURE

CHILLER - 2TR

PREFORM AUTOLOADING – NO

HYDROLIC LOCKING – YES

HYDROPNEUMATIC LOCKING – YES

ELECTRICAL LOAD WITH ACCESSORIES – 30 HP

POWER CONSUMPTION – 20 HP

SIZE (IN FEET) – 6* 6 *7

MACHINE MODEL NO. SPBM -20 LIT JAR

MACHINE MODEL NO.- SPBM-20 LIT. JAR

MACHINE DETAIL - SEMIAUTOMATIC 20 LIT.

OUTPUT / HOUR – 90 JAR / HOUR

VOLUME – MIN – 10 LIT. , MAX- 20 LIT.

HIGH PRESSURE AIR COMPRESSURE – 20 HP, 30 KG

cm2, 53CFM

LOW PRESSURE COMPRESSURE - NO

AIR DRYER – HIGH PRESSURE

CHILLER - 2TR

PREFORM AUTOLOADING – NO

HYDROLIC LOCKING – YES

HYDROPNEUMATIC LOCKING – YES

ELECTRICAL LOAD WITH ACCESSORIES – 50 HP

POWER CONSUMPTION – 30 HP

SIZE (IN FEET) – 7 * 7 *7

MACHINE MODEL NO. APBM-1C (SINGLE CAVITY)

MACHINE MODEL NO.- APBM – 1C ( SINGLE)

MACHINE DETAIL - AUTOMATIC 1 CAVITY FOR JAR & BOTTLE

OUTPUT / HOUR – 1100 BOTTLES & 450 JAR 5KG / HOUR

VOLUME – MIN – 100 M.L. , MAX- 2 LIT.

HIGH PRESSURE AIR COMPRESSURE – 20 HP , 30 KG/cm2, 53CFM

LOW PRESSURE COMPRESSURE - NO

AIR DRYER – HIGH PRESSURE

CHILLER - 2TR

PREFORM AUTOLOADING – OPTIONAL

HYDROLIC LOCKING – YES

HYDROPNEUMATIC LOCKING – YES

ELECTRICAL LOAD WITH ACCESSORIES – 30 HP

POWER CONSUMPTION – 18 HP

SIZE (IN FEET) –5.5 * 5 *7

MACHINE MODEL NO. APBM 2C

MACHINE MODEL NO.- ABPM-2C (DOUBLE)

MACHINE DETAIL - AUTOMATIC 2 CAVITY FOR BOTTLE

OUTPUT / HOUR – 2000 BOTTLE / HOUR

VOLUME – MIN - 100 M.L. , MAX-2 LITER

HIGH PRESSURE AIR COMPRESSURE – 20 HP , 30 KG/cm2 , 53CFM

LOW PRESSURE COMPRESSURE - 10 HP , 10 KG/cm2 , 27CFM

AIR DRYER – HIGH PRESSURE

CHILLER - 3TR

PREFORM AUTOLOADING – OPTIONAL

HYDROLIC LOCKING – YES

HYDROPNEUMATIC LOCKING – NO

ELECTRICAL LOAD WITH ACCESSORIES – 40 HP

POWER CONSUMPTION – 25 HP

SIZE (IN FEET) – 6* 5.5 *7

MACHINE MODEL NO. APBM 4C

MACHINE MODEL NO.- ABPM-4C (FOUR)

MACHINE DETAIL - AUTOMATIC 4 CAVITY FOR BOTTLE

OUTPUT / HOUR – 4000 BOTTLE / HOUR

VOLUME – MIN - 100 M.L. , MAX- 1 LITER

HIGH PRESSURE AIR COMPRESSURE – 40 HP , 30 KG/cm2 , 90CFM

LOW PRESSURE COMPRESSURE - 15 HP , 10 KG/cm2 , 35CFM

AIR DRYER – HIGH PRESSURE

CHILLER - 5TR

PREFORM AUTOLOADING – YES

HYDROLIC LOCKING – YES

HYDROPNEUMATIC LOCKING – NO

ELECTRICAL LOAD WITH ACCESSORIES – 55 HP

POWER CONSUMPTION – 35 HP

SIZE (IN FEET) – 7.5* 6 *7

MACHINE MODEL NO. APBM 4C

MACHINE MODEL NO.- APBM – 6C

MACHINE DETAIL - AUTOMATIC 6 CAVITY FOR BOTTLE

OUTPUT / HOUR – 6000 BOTTLES / HOUR

VOLUME – MIN – 100 M.L. , MAX- 500 M.L.

HIGH PRESSURE AIR COMPRESSURE – 60 HP, 30 KG/cm2, 135CFM

LOW PRESSURE COMPRESSURE - 15 HP ,10 KG/cm2 35CFM

AIR DRYER – HIGH PRESSURE

CHILLER - 5TR

PREFORM AUTOLOADING – YES

HYDROLIC LOCKING – YES

HYDROPNEUMATIC LOCKING – NO

ELECTRICAL LOAD WITH ACCESSORIES – 75 HP

POWER CONSUMPTION – 50 HP

SIZE (IN FEET) – 8 * 7 *7

MACHINE MODEL NO. APBM 4C

| S.no | Modal No. | ARFC 30 BPM | ARFC 40 BPM | ARFC 60 BPM | ARFC 90 BPM | 120 BPM |

|---|---|---|---|---|---|---|

| 1 | Output/hr ( ref 1 Ltr Size ) | 1800 | 2400 | 3600 | 5400 | 72002 |

| 2 | Configuration Rinsing-Filling-Capping | 6.6.3 | 6.8.3 | 10.10.5 | 16.16.6 | 20.20.8 |

| 3 | Bottle Size Range | 200ml to 2000ml | 200ml to 2000ml | 200ml to 2000ml | 200ml to 2000ml | 200ml to 2000ml |

| 4 | In Feed Air Conveyor | 6 Feet | 6 Feet | 10 Feet | 10 Feet | 15 Feet |

| 5 | Out Feed Air Conveyor | 15 Feet | 20 Feet | 20 Feet | 24 Feet | 24 Feet |

| 6 | Machine Type | Fully Mechanical | Fully Mechanical | Fully Mechanical | Fully Mechanical | Fully Mechanical |